Transparent Anti-Static Acrylic Sheet

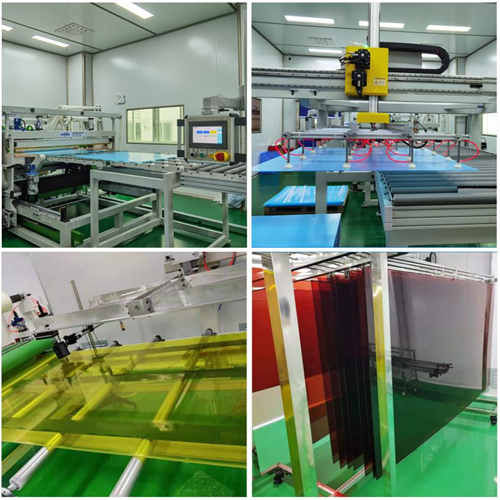

The Transparent Anti-Static Acrylic Sheet is kind of special surface treatment base on optical acrylic sheet to prevent the static, the base acrylic sheet is made from 100% pure PMMA pellets in the 10 thousands grade purification workshop. And the surface chemical treatment for anti-static is also in the dust-free environment.

The Anti-static Acrylic Sheet features consistent surface resistivity of 109 to 1011 ohms/square, making them suitable for OEMs and processors who require best possible ESD protection and dust control. In case higher conductivity and lower surface resistance (107 to 108 ohms/square) are required.

The Custom Cut Acrylic Plexiglass widely used in Electrical & Electronic, optics, medical and clear production environment, such as clean rooms, medical equipment, battery cells, and electronic trays.

1. What’s the Transparent Anti-Static Acrylic Sheet

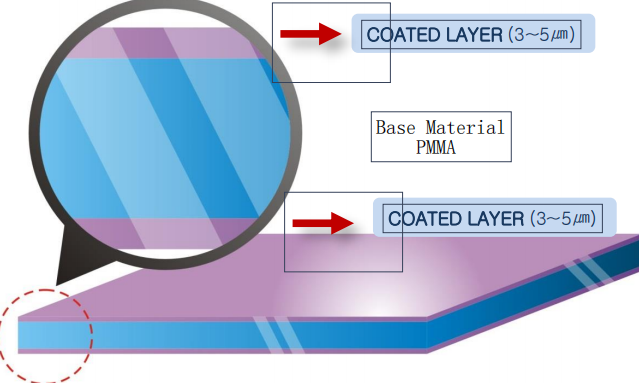

Do the surface chemical treatment base on optical acrylic sheet, which the chemical layer is kind of Conductive organic membrane, and the thickness is about 3-5 μm each side, this will make the acrylic sheet with anti-static function and meanwhile enhance the surface hardness,make it more anti-scratch

2, The Benefit of anti-static acrylic sheet

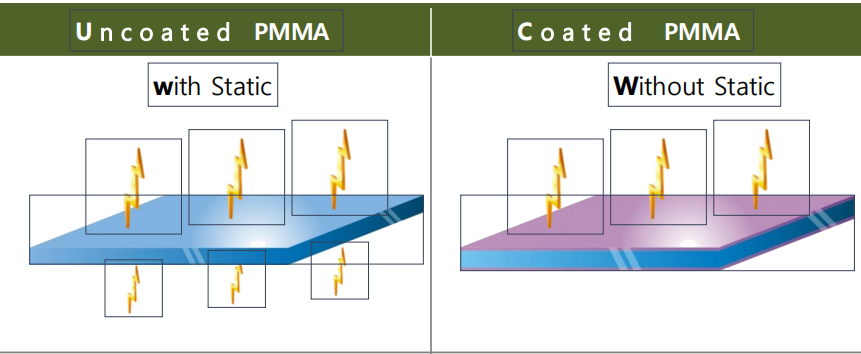

Normal acrylic sheet with electricity static and the electrostatic force act on the dust and then be transfer to the surface of the sheet, when contact with external conductor will have voltage discharge, this will cause the product quality problem for the semiconductor component;

While the acrylic sheet with special surface chemical treatment can effectively prevent the adsorption and accumulation of the dust, this will not cause quality problem caused from the static.

3, Transparent Anti-Static Acrylic Sheet Application:

Anti static acrylic is ideal for any applications involving electricity or electrically conductive surfaces including static control shields, glove boxes, conveyor line covers, electronic equipment and more. For more antistatic plastic sheets

4, Material characteristics

(一)

Size | 1250*2450 2050*3050 | ||

Thickness | 1-10mm 12mm 15mm 20mm | ||

Description | Special coating on the surface to prevent the static, it is widely used in Electrical & Electronic, optics, medical and clear production environment. | ||

Character | 1. Excellent surface hardness(PMMA:4H PC:HB) | ||

Testing Item | Testing Tools | Testing Methods/Condition | Result |

VLT/transmittance | Transmittance tester | Direct testing | >88% |

Haze | Haze Meter | ASTM D1001 | <0.5%<> |

Anti static index | Anti static tester | 10^6-10^Ω | stable |

Adhesion | Boiling tester | 30mins in Boiling water | 5B |

Hardness | Hardness Pencil Tester | ASTM D3363 | 4H |

Wear resistance | Taber Wear resistance tester | 500g/c㎡, 60rpm 500 cycles 1000g/c㎡, 60rpm 1000 cycles | HAZE:3.25%

HAZE:6.5%-10% |

Waterproof | Boiling tester | Soaking in water 24h | No change |

(二)

Properties | Test method | Test condition | Result | |

Density | ASTM D792-08 | 23±0.5℃ | 1.19g/cm3 | |

Water absorption | ASTM D570-98 | 50±3℃,24h | 0.27% | |

Light luminous transmission | ASTM D1003-07 | Specimen thickness:3.0mm | 93.0% | |

Haze | <0.3%<> | |||

Heat distortion temp | ASTM D648-07 | Width:3.00mm,120℃/h Load:1.82MPa | 88.4℃ | |

Vicat softening temperature | ASTM D1525-09 | Thickness:3.0mm,120℃/h Load:50N | 104.0℃ | |

Mold shrinkage | ASTM D955-08 | 23±2℃,50±5%RH,48h | Parallel to flow | 0.37% |

Perpendicular to flow | 0.31% | |||

Tensile strength | ASTM D638-10 | Thickness:3.0mm,5mm/min | 61.8MPa | |

Elongation at break | 3.0% | |||

Tensile modulus | 3270 MPa | |||

Flexural strength | ASTM D790-10 | 3.0mm,1.3mm/min 48mm | 107 Mpa | |

Flexural modulus | 3310 MPa | |||

IZODnotched lmpact strength | ASTM D256-10 | Width: 3.0mm 1J | 15J/m | |

(HRR) Rockwell hardness(HRR) | ASTM D785-08 | Width:6.0mm | 123 | |

20mm Vertical Burning Test | UL 94 | Specimen: 3.0mm | HB/V2 | |