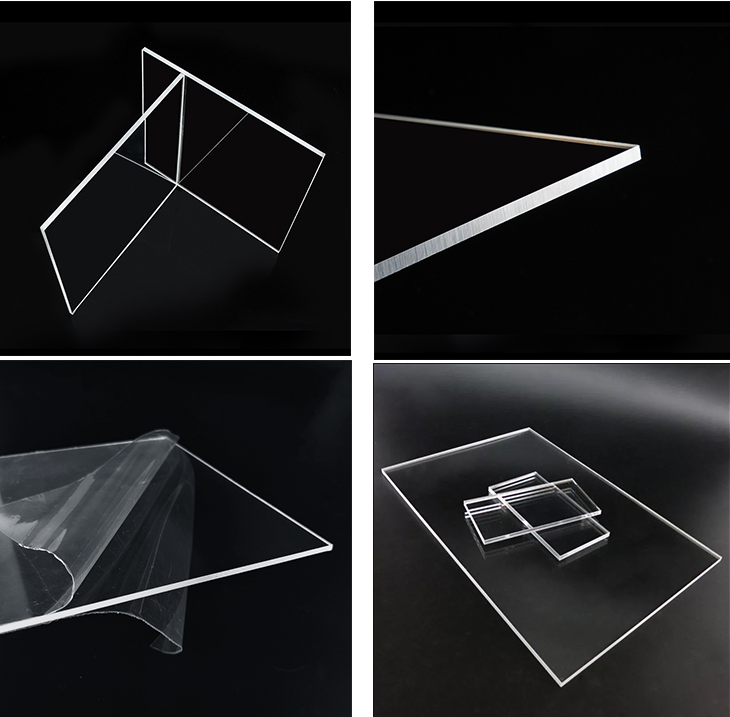

PMMA Clear Material, commonly known as acrylic or organic glass, is a thermoplastic with high transparency, excellent optical properties and good mechanical properties. It has become an ideal substitute for glass with its excellent light transmittance, weather resistance, processability and cost-effectiveness.

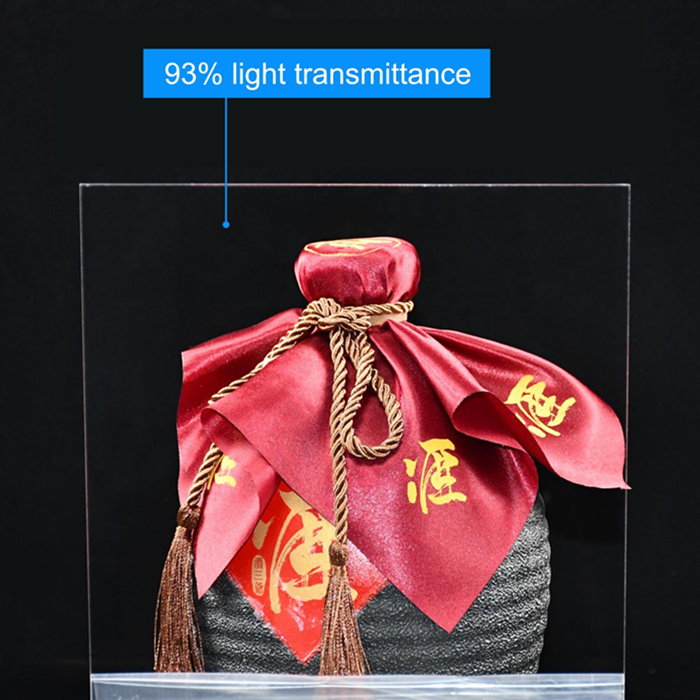

PMMA has a light transmittance of up to 92%, close to glass (95%), but weighs only half of glass and has stronger impact resistance (7-18 times that of glass). This feature makes it excellent in scenes that require a clear view, such as car headlights, building skylights, etc.

It has excellent UV resistance and is not easy to fade, yellow or brittle when exposed to outdoor environments for a long time. It is suitable for products such as billboards and outdoor lamps that need to withstand wind and sun for a long time.

It has strong tensile and impact resistance. PMMA that has been stretched can even be used for bulletproof glass and military aircraft canopies. Although its hardness is lower than that of glass, its wear resistance can be significantly improved through surface hardening treatment.

It has strong corrosion resistance to chemical substances such as acid, alkali, and salt, but it needs to avoid contact with organic solvents such as dichloroethane and chloroform.

Good processing performance

It can be processed by various processes such as injection molding, extrusion, casting, and thermoforming. It is easy to bond, cut, drill, screen print, etc., and is suitable for customized production of complex shapes.

The glass transition temperature is 104℃, the maximum continuous use temperature is between 65℃-95℃, and the heat deformation temperature is about 96℃ (1.18MPa), which is suitable for non-high temperature environments.

Low dielectric constant and loss, strong arc resistance, suitable for the field of electronic appliances.

It meets the green material standards and can be recycled and reused by physical or chemical methods.

PMMA particles are heated and melted by an injection molding machine and injected into the mold, cooled and shaped. It is suitable for making complex-shaped products such as lamps and instrument panels.

Used to produce profiles such as sheets and pipes, such as building skylights, advertising light boxes, etc.

Pour liquid PMMA into a mold for curing, suitable for the production of large-size sheets or special-shaped parts.

After the PMMA sheet is heated and softened, it is pressed into a specific shape through a mold, such as a car rearview mirror, bathtub, etc.

Including hardening coating, anti-glare treatment, etc., to improve wear resistance and optical properties.

Skylights and curtain walls: PMMA's high light transmittance makes the interior of the building brighter while reducing the structural burden.

Fiber optic lighting: As an optical fiber material, it achieves efficient light transmission and is used in lighting systems in large public places such as airports and shopping malls.

Lighting system: PMMA materials are widely used in the manufacture of car headlights, taillight covers and interior lights, providing clear lighting effects.

Interior parts: PMMA materials are used in instrument panels, control panels and decorative strips to improve aesthetics and chemical resistance.

Exterior parts: sunroofs, side windows and other parts take advantage of PMMA's light weight and weather resistance to help lighten cars and improve fuel efficiency.

Artificial joints and bones: PMMA, as a manufacturing material for artificial joints and bones, provides high-strength support and wear resistance, and is suitable for artificial joints, dental restorations and other fields.

Biomedical: Contact lenses, intraocular lenses, etc. take advantage of their biocompatibility to ensure safe cooperation with the human body.

Billboards and light boxes: PMMA has a smooth surface and good light transmittance, making the advertising content more bright and eye-catching, and weather resistance ensures long-term stability.

Display cabinets and exhibition stands: It has strong machinability and is suitable for making exhibits of complex shapes to enhance the display effect.

Artificial joints and bones: PMMA's high strength and wear resistance make it an ideal material for artificial joints and bones.

Dental restoration materials: Dental trays and dental braces take advantage of their transparency and aesthetics, while chemical resistance can resist corrosion in the oral environment.

Drug delivery systems and biosensors: Biocompatibility and stability make it an ideal material to meet different drug release and sensing needs.

Glasses and camera lenses: Excellent optical performance ensures clear imaging effects.

Optical instruments: PMMA's low light scattering and refraction properties make it perform well in optical products.

Billboards and light boxes: Good light transmittance and strong weather resistance, suitable for long-term outdoor use.

Display cabinets and exhibition stands: Strong processability, suitable for making exhibits with complex shapes.

Refrigerator door panels and washing machine windows: High transparency and easy cleaning characteristics enhance the beauty and practicality of products.

Lighting lamp covers and bathtubs: Weather resistance ensures long-term performance.

Car taillight covers and dashboards: Lightweight and impact-resistant, meeting the high requirements of transportation for materials.

Aircraft windows: High transparency improves the quality of driving vision.

Maintenance and cleaning

Use a soft cloth or lint-free cloth to wipe to avoid scratching the surface.

Use warm water and a small amount of neutral detergent (such as dishwashing liquid) to gently wipe, and avoid strong acid and alkaline detergents.

Stubborn stains can be treated with alcohol or special detergents.

Maintenance suggestions

Check the integrity of the product regularly, avoid sharp objects from contacting the surface, and prevent scratches.

Keep away from high temperature and heavy pressure during storage, and keep in a dry and ventilated environment.

Minor scratches can be treated with special repair agents, and deeper scratches are recommended to contact professional repairs.