frosted acrylic sheets and glass panels are modern materials popularly used in construction and desigining. One has to understand the materials well in order to make the right selection for a given project, so that a balanced definition of form and function is achieved.

1. Material Composition and Durability

Frosted Acrylic Sheets:

A thermoplastic material that has a mat finish is known as frosted acrylic. Frosted acrylic weighs less, is not prone to shattering and is durable therefore it can be used in multiple environments where safety and resistance to impact is crucial.

Glass Panels:

Frosted acrylic is a heavy thermoplastic and it is a silica made material which is prone to shattering and is easier to scratch due to its reduced density. Tempered glass is most commonly used nowadays as it is much safer as it does not shatter instead it breaks off in small pieces that are less dangerous.

2. Weight and Handling

Acrylic Sheets:

Due to its low density acrylic is half the weight of glass which facilitates large projects to handle the acrylic sheets for installation easily instead of glass panes.

Glass Panels:

In spite of high strength glass requiring more labor and equipment for transportation and installation, its density makes it heavier. In large amounts, glass panels may need special equipment or extra manpower for proper management.

3. Aesthetic Qualities and Transparency

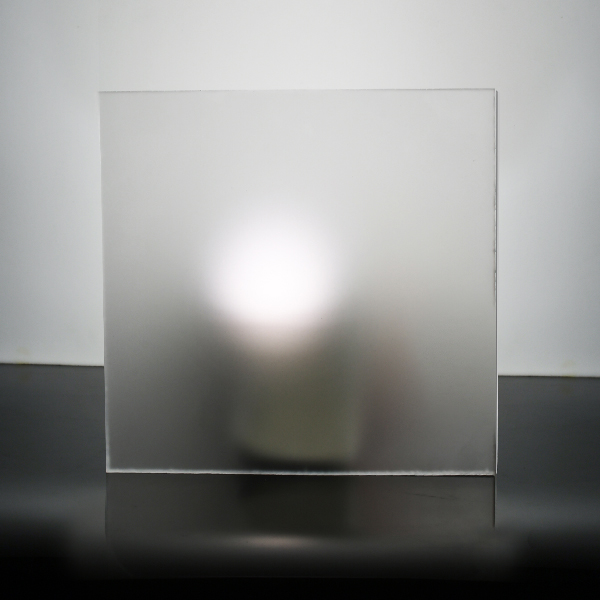

Frosted Acrylic Sheets:

Such sheets allow a little light to come through but not enough to destroy privacy. The matte effect produced by frosted acrylic allows it to be used decoratively in modern offices, stores and houses.

Glass Panels:

This technology has the same functional capabilities as glass but it has a lower surface quality. Once polished it has a decent optical clarity rating and is fleshy in look thus, it is often used in high end interiors and architecturally designed places.

4. Cost Effectiveness

Acrylic Sheets:

Acrylic sheet has a lower cost of two kinds, manufacturing and transportation, therefore frosted acrylic is very useful in projects that cannot spend too much on costs, or like use it on a tampered glass.

Glass Panels:

In relation to other glass types, tempered or specialized glass cost more due to their manufacturing techniques and material properties. Even so, certain uses would be able to overlook the overall cost due to the opportunity and aesthetic costs that are indicated in the glass.

5. Uses and Adaptability

Acrylic Sheets:

Acrylic is one of the most adaptable substances since it can be shaped, cut or molded into different forms without breaking. It is an ideal choice for signs, display, cases, partitions and decorative panels.

Glass Panels:

With regard to the flexure rigidity of raw material, glass has a lesser allowance for shaping but is useful in places where clarity, strength and anti-scratch are top requirements. It is generally used as windows, doors, shower enclosures and balcon siers.

6. Concerns to the Environment

Acrylic Sheets:

Acrylic is manufactured from petrochemicals, however being long lasting aids in minimizing breakages and frequent changes of the end products. Some forms of acrylic are even recyclable hence contribute towards sustainable development efforts.

Glass Panels:

Glass is a material which is manufactured out of raw materials and is fully recyclable making it more eco-friendly. Nonetheless, glass is heavier and requires a high amount of energy during its production process making it detrimental to eco-friendliness in some areas.

Conclusion: How to Select the Right Material For Your Needs.

Frosted acrylic sheets as well as glass panels have certain pros as well as cons that will be applicable for certain requirements. Acrylic is the best material to use if your project needs lightweight, impact resistant and cost-effective materials while glass can be used if one is looking at classical designs with strength and classic high end look.

When choosing between the two, consider the following aspects such as use, financial resources, design aspects, and effects on the environment. This understanding of the core differences will allow you to meet the expectations of your project.