“Light Guide Plate for Blue Sky Light” Here, “Blue Sky Light” may be the name of a specific scene or product, and the Light Guide Plate (light guide plate, LGP for short) is an important optical component. Light guide plate is the use of optically grade acrylic (PMMA) /PC plate, through high-tech means on the bottom of the plate to produce a very high reflectivity and non-absorbent guide point. These points of light can guide the light emitted from the lamp, conducting and scattering inside the plate, and finally achieving the effect of converting a line or point light source into a surface light source.

Before Illuminated After Illuminated

Working principle

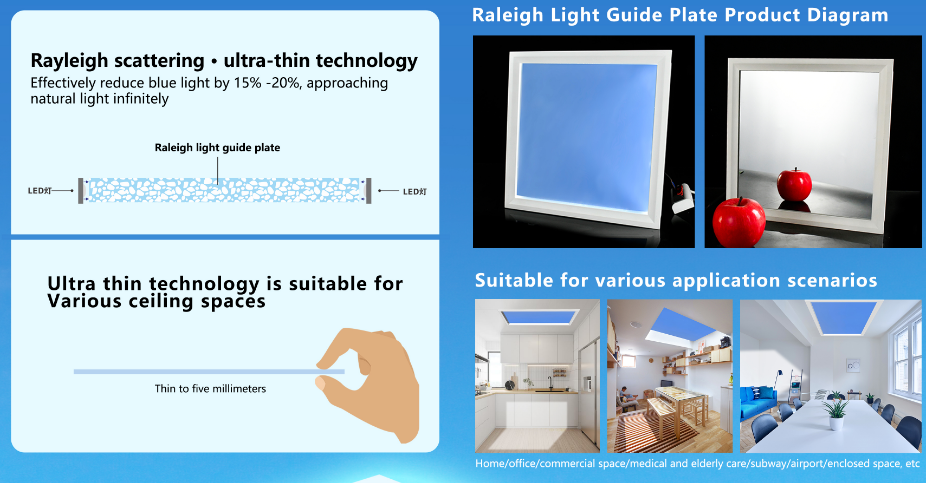

The working principle of the light guide plate is based on the principle of total reflection and scattering of light. When the light is emitted from the light source and shines into the light guide plate, the light will be reflected several times inside the plate. When the light meets the guide point, it will be scattered, and some of the light will be emitted from the front of the light guide plate to form a surface light source. By reasonably designing the layout and size of the light guide point, the uniform conduction and scattering of light in the light guide plate can be realized, so as to achieve the ideal luminous effect.

Classification and Characteristics

Light guides can be classified according to shape, dot type, light entry mode and forming mode. Different types of light guides have different characteristics and application scenarios. For example:

The plate light guide plate is usually rectangular and is suitable for occasions where a large area of uniform light is required.

The wedge plate (inclined plate) has a shape characteristic of thick on one side and thin on the other, which is suitable for occasions where special luminous effects are required.

The printed light guide plate prints the dot on the reflective surface by printing, which has the advantages of low cost and simple process, but the service life is relatively short.

The non-printing light guide plate is made of dot by chemical etching, precision mechanical characterization, etc., which has the advantages of more uniform light guide and more stable effect.

In addition, the light guide plate also has the characteristics of simple process, splicing, energy saving and high efficiency. It can be cut into different sizes and shapes as needed to suit the needs of different occasions. At the same time, the light guide plate has a long service life and can emit light stably for a long time, providing a reliable light source support for various applications.

Application:

Light guide plate is mainly used in liquid crystal display and lamps and other fields. In the liquid crystal display, the light guide plate is an important part of the backlight module, which can evenly conduct the light emitted by the LED and other light sources to the liquid crystal screen, so that the screen shows a clear image. At the same time, the light guide plate is also widely used in advertising light boxes, sign plates and other occasions because of its ultra-thin, ultra-bright, energy saving, environmental protection and other characteristics.