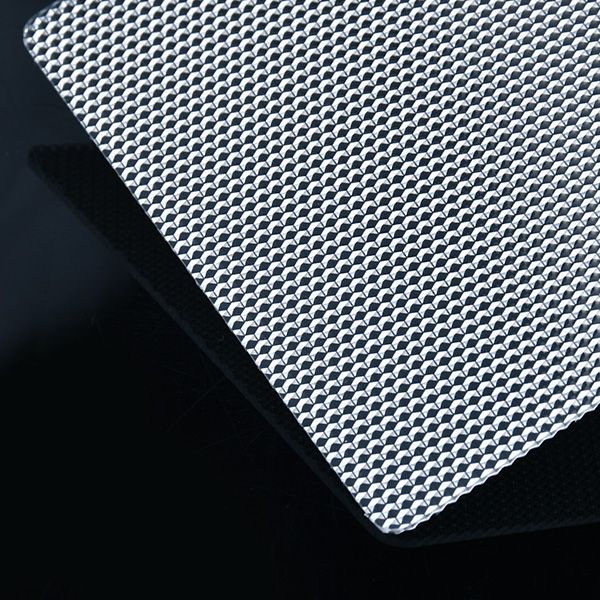

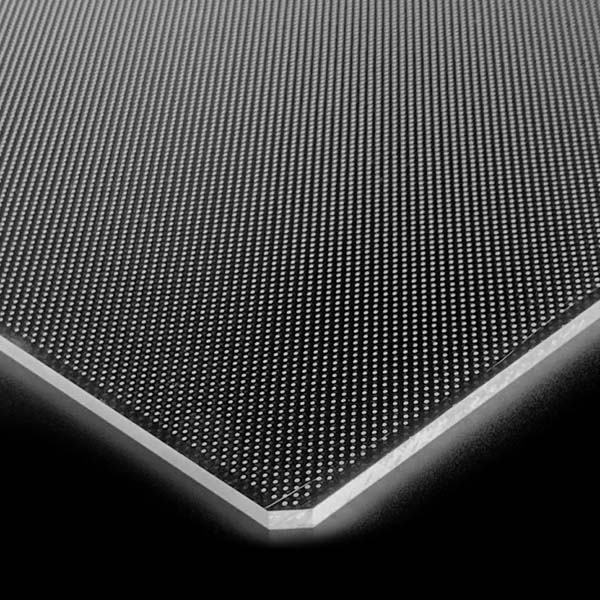

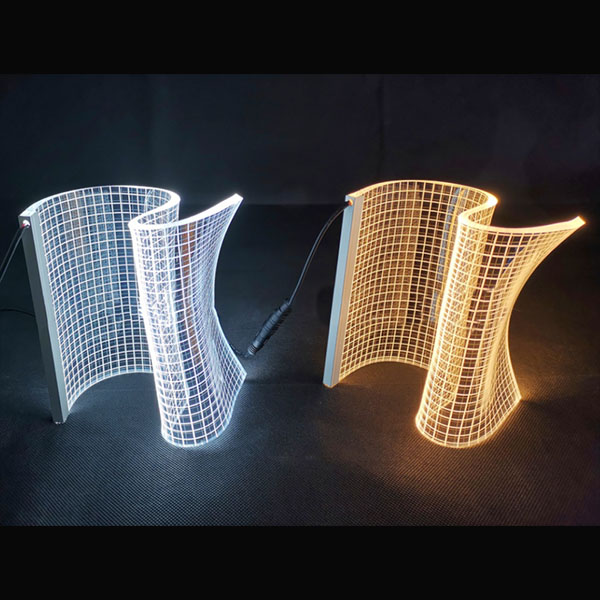

Light Guide Acrylic Sheet distributes light evenly to the entire plane by designing microstructures (such as dots, prisms, etc.) on the surface or inside of the acrylic substrate, using the principles of light reflection, refraction and scattering. Compared with traditional light sources, light guide plates can significantly improve lighting efficiency, reduce energy consumption, and achieve lightweight design. Its manufacturing processes include screen printing, laser engraving, V-cut microstructure processing, etc., with mature technology and controllable costs.

Length (MM) | Width (MM) | Thickness (MM) |

3000/1200/600/300 | 2000/1200/600/300 | 1.8-8.0 |

Available Material | PMMA | |

Available Technology: | Laser etch (PMMA Material)

| |

Chamfer: | C5 or C7 | |

Light Input | Four way, Two way or One way | |

Optical performance

High light transmittance: The light transmittance reaches 92%-93%, which is close to optical glass, ensuring efficient light transmission;

Low haze: The haze is ≤1%, reducing light scattering and improving light efficiency;

Uniform light guide: The microstructure design achieves uniform light distribution to avoid bright spots or dark areas.

Physical properties

Lightweight and high strength: The density is 1.19-1.20 g/cm³, the weight is only half of that of glass, and the impact strength is 7-18 times that of glass;

Strong weather resistance: Anti-ultraviolet and aging resistance, no yellowing after 5-8 years of outdoor use;

Dimensional stability: Low thermal expansion coefficient, small dimensional change under temperature changes.

Processing performance

Easy to form: It can be formed by hot bending, laser cutting, CNC processing and other methods;

Surface treatment: Supports secondary processing such as silk screen printing, coating, and spraying to meet personalized needs.

Environmental protection and safety

Non-toxic and harmless: Comply with environmental protection standards such as RoHS and REACH;

Flame retardant: Optional UL94 V-0 grade flame retardant material to improve safety of use.

Raw material selection

Optical-grade PMMA particles or sheets are used to ensure the purity and light transmittance of the material.

Manufacturing process

Microstructure design: Design microstructures such as dots and prisms through computer simulation;

Surface treatment: Use screen printing, laser engraving or V-cut technology to process microstructures on the acrylic surface;

Post-processing: Including cleaning, drying, film lamination and other processes to ensure surface finish.

Key technologies

Light guide dot design: Optimize light efficiency by adjusting dot density, size and shape;

Optical-grade mold: High-precision mold ensures microstructure replication accuracy;

UV curing technology: Rapidly cure ink to improve production efficiency.

Lighting industry

Ultra-thin light box: The light guide plate converts LED point light source into a uniform surface light source, and the thickness can be as thin as 1-3cm, which is suitable for shopping malls, airports and other places;

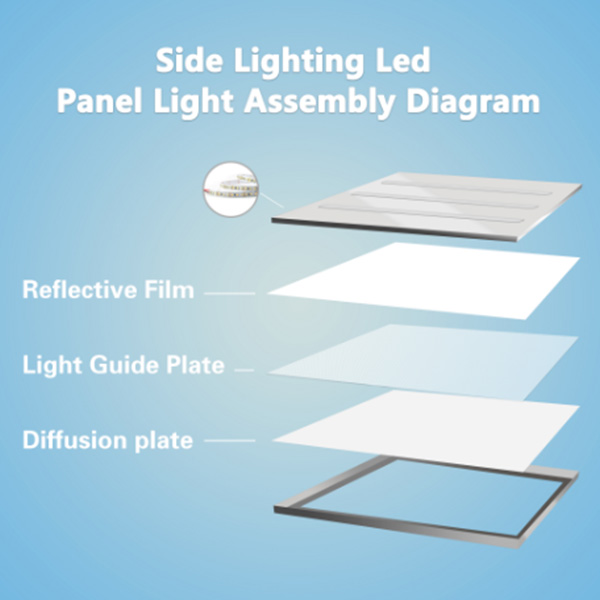

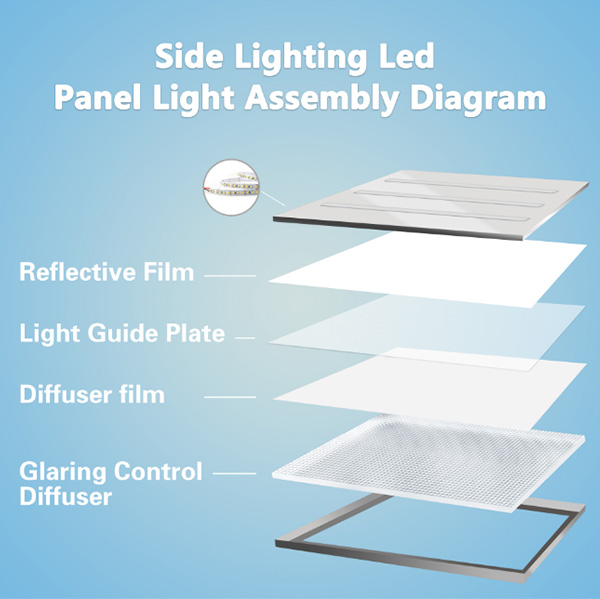

Panel light: As a diffusion plate, it improves the uniformity of LED panel light and reduces glare;

Outdoor advertising: Highly weather-resistant light guide plates are used for outdoor billboards to ensure long-term use without fading.

Display technology

LCD backlight module: The light guide plate is the core component of the LCD display, providing uniform backlight and improving the display effect;

OLED encapsulation: As an encapsulation material, it protects OLED devices from water vapor and oxygen erosion.

Architectural decoration

Lighting ceiling: The light guide plate introduces natural light into the room to reduce the energy consumption of artificial lighting;

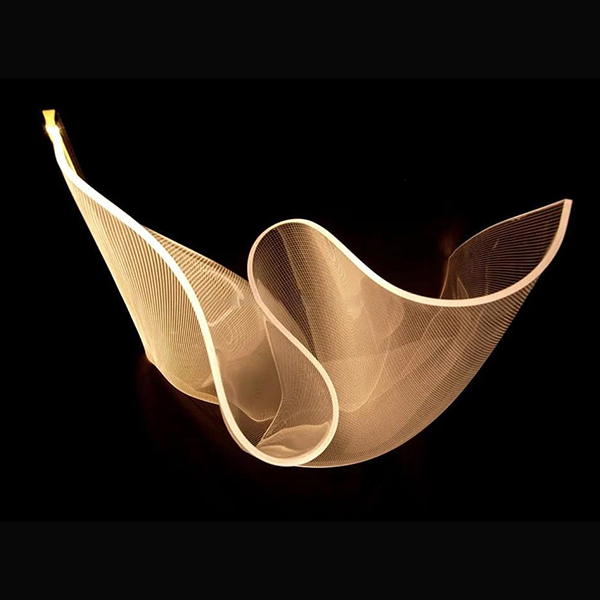

Art installation: Through special-shaped cutting and surface treatment, creative lighting art works are created.

Automotive industry

Car lights: The light guide plate is used for daytime running lights, atmosphere lights, etc. to achieve uniform lighting effects;

Instrument panel: As a backlight material, it improves the readability of the instrument panel.

Medical equipment

Observation window: High-transmittance light guide plates are used in equipment such as microscopes and blood analyzers to ensure clear observation;

Surgical lights: Provide uniform shadowless lighting and improve surgical safety.

Emerging fields

VR/AR equipment: Lightweight light guide plates are used for optical lenses to enhance the visual experience;

Smart home: The light guide plate is integrated into smart lamps to achieve dynamic light effect control.

Cleaning Recommendations

Wipe with a soft cloth dipped in clean water or neutral detergent, avoid using organic solvents such as alcohol and acetone;

Regular cleaning can prevent dust accumulation from affecting light efficiency.

Precautions for use

Avoid high temperature (>100℃) environment to prevent the material from softening and deforming;

Prevent sharp objects from scratching the surface and affecting light transmittance.

Storage Conditions

Store in a cool and dry place, avoid direct sunlight;

Stacking height should not exceed 1 meter to prevent pressure loss.

Q: What is the difference between light guide acrylic sheet and ordinary acrylic sheet?

A: The light guide plate must have high light transmittance, low haze and specific microstructure. Ordinary acrylic sheet cannot meet the light guide requirements.

Q: How to choose the appropriate thickness of the light guide plate?

A: According to the light source type (LED/lamp tube) and size, the general thickness is 1-5mm, and the larger size needs to increase the thickness.

Q: Does the light guide plate support customized design?

A: It supports customization of microstructure, size, shape and surface treatment, and design drawings or samples are required.

Q: What is the life of the light guide plate?

A: Under normal use conditions, the life can reach 5-8 years. Weather-resistant materials should be selected for outdoor use.

Q: How to reduce the cost of the light guide plate?

A: Optimizing microstructure design, selecting domestic materials or bulk purchasing can reduce costs.

Q: Does the light guide plate meet environmental protection standards?

A: It complies with RoHS, REACH and other standards, and some products can pass UL and CE certification.