Perspex sheet, also known as acrylic sheet, is a highly versatile material widely used across various industries due to its unique combination of properties. Made from polymethyl methacrylate (PMMA), Perspex offers excellent optical clarity, which rivals that of glass, while being half the weight. This lightweight nature makes it easier to handle, transport, and install, reducing both labor and material costs.

Extensive Industry Experience: With over 10 years in the manufacturing and supplying of Polycarbonate and Acrylic sheets, we have developed deep expertise and established two reputable brands, "J.K Optics" and "KunXin Plas," specializing in optical diffusion sheets and textured panels.

High-Quality Materials and Advanced Equipment: We use top-grade raw materials from Mitsubishi, Japan, and have introduced advanced Co-extrusion equipment. Our production processes, including extrusion, calendaring, cooling, and masking, are conducted in dust-free conditions to ensure the highest quality.

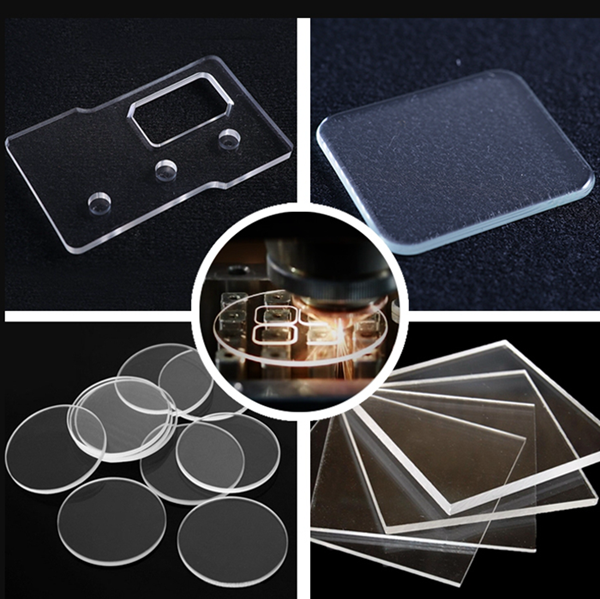

Wide Range of Products and Applications: Our product lineup includes Acrylic Diffuser Plates, PC Diffuser Films, PS Diffuser Sheets, Acrylic Textured Panels, and Optical PMMA Sheets. These products are widely used in LED light fixtures, ceiling lights, architectural applications, display panels, and digital photo frames.

Commitment to Innovation and Customer Support: We continually reinvest in research and development and adopt the latest technology to introduce new products and maintain quality and cost control. This commitment allows us to help our customers meet the evolving challenges of the global marketplace, with a monthly production capability of 600 tons, positioning us as a leading company in China's optical plastic industry.

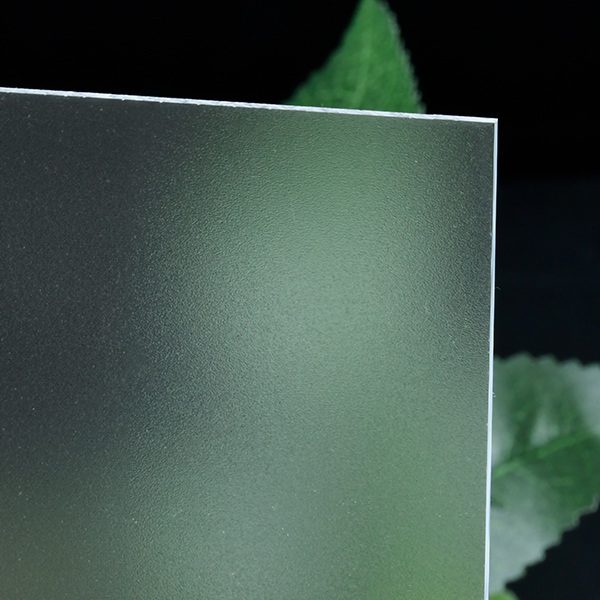

The Satinice acrylic sheet’s efficient combination of light

transmission and diffusion, it’s satin ice surface is eye-catching, resilient, contemporary, technologically advanced and cost efficient. And acrylic is UV stable and the colour is not affected by sunlight, you can safely apply it inside and outside.it’s very recommended for constructive applications like floors, walls and full bars and desks, and also popular for esthetic applications such as bar fronts, signage, decors, displays and so on.

Architectural Lighting:

Used in architectural lighting fixtures and designs to create soft, diffused illumination in spaces such as offices, hotels, and residential buildings.

Retail Displays:

Employed in retail environments for showcasing products in a flattering light, reducing glare and highlighting merchandise effectively.

Lighting Fixtures:

Incorporated into light diffusers, lens covers, and lampshades for ceiling lights, pendant lights, wall sconces, and other lighting fixtures to create a gentle, glare-free ambiance.

Furniture and Décor:

Applied in furniture pieces, such as shelving units, tables, and countertops, to add a frosted aesthetic and diffuse light in modern and contemporary interiors.

The frosted satin ice acrylic can be thermoformed for domed or shaped fixtures and will retain its frosted finish throughout the thermoforming and can easily to the following process: lasering, sawing, milling,faceting,polishing,sanding and printing.

What is a Perspex sheet used for?

Perspex sheets are used in various applications such as signage, protective barriers, windows, displays, and lighting. They offer excellent optical clarity, durability, and weather resistance, making them suitable for both indoor and outdoor use.

Is Perspex the same as acrylic?

Yes, Perspex is a brand name for acrylic sheets. Both are made from polymethyl methacrylate (PMMA) and share similar properties like high optical clarity, lightweight, and impact resistance, making them popular in construction, design, and manufacturing.

How do you cut Perspex sheets?

Perspex sheets can be cut using various tools such as a fine-toothed saw, laser cutter, or a scoring knife for thin sheets. Proper support and slow, steady cutting ensure clean edges and prevent cracking or chipping during the process.

Can Perspex sheets be used outdoors?

Yes, Perspex sheets are ideal for outdoor use due to their UV resistance, which prevents yellowing and degradation over time. They are commonly used in signage, outdoor displays, and glazing where exposure to sunlight and weather elements is a concern.

How do you clean Perspex sheets?

Perspex sheets should be cleaned with a soft cloth, mild soap, and water. Avoid abrasive cleaners or rough materials that could scratch the surface. For stubborn stains, a specialized acrylic cleaner can be used to maintain the sheet's clarity.

Is Perspex sheet shatterproof?

While Perspex is not entirely shatterproof, it is significantly more impact-resistant than glass. When broken, it does not shatter into sharp, dangerous pieces, making it a safer alternative in environments where safety is crucial.

Jiangmen Kunxin New Material Technology Co., Ltd has got over 10 years in Polycarbonate sheets 、Acrylic Sheets and polystyrine manufacturing and supplying.